Understanding Plastic Injection Mold Design: A Comprehensive Guide

For manufacturers and engineers, the plastic injection mold is the most critical tool in the production cycle. While every mold is customized for a specific product, the underlying engineering principles remain constant. A well-designed mold ensures part consistency, reduces cycle times, and extends the lifespan of the tool.

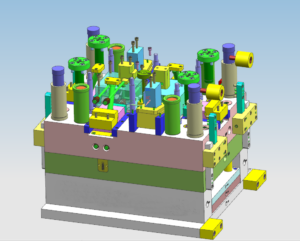

The basic structure of an injection mold consists of three functional groups: the Gating System, Molded Parts, and Structural Components.

1. The Gating System: The Pathway for Success

The gating system is the "plumbing" of the mold. It guides the molten plastic from the injection machine nozzle into the mold cavity.

The Sprue: The primary entry point. To prevent leakage and "freezing" at the nozzle, the sprue inlet is typically 0.5mm to 1.0mm larger than the machine nozzle. A standard 3° to 5° taper is added for easy ejection.

Cold Slug Well: A critical "trap" at the end of the sprue that catches the cooler material from the nozzle tip. This prevents cold spots from clogging the gates or creating blemishes on the final part.

Runners (Shunts): These channels distribute plastic to multiple cavities. Professional molders prefer trapezoidal or circular runners for balanced flow and minimal pressure drop.

The Gate: The narrowest point in the system. It controls the velocity of the melt and acts as a "seal" once the part is full, preventing backflow.

2. Cavity and Core: The Heart of the Shape

The Molded Parts are what define the final geometry and surface texture of your product.

Cavity (Female): Forms the exterior surface.

Core (Male): Forms the interior features (like holes or ribs).

Precision Finish: To ensure easy "stripping" or ejection, the surface roughness is usually kept at Ra < 0.32µm. For high-gloss or transparent parts, vacuum heat treatment and mirror polishing are applied to the tool steel.

3. Venting and Cooling: Ensuring Part Quality

Even the best gating system will fail without proper venting and thermal management.

Venting (Air Escapes): As plastic fills the mold, air must escape. Without proper vent slots (usually 0.03mm to 0.05mm deep), the air compresses, causing "burn marks" or "short shots."

Cooling Systems: Efficiency is key. Most Chinese injection mold companies utilize internal water channels to regulate temperature. Uniform cooling is the secret to preventing part warpage and achieving fast cycle times.

4. Structural Components: The Backbone

The structural parts, such as guide pillars, ejector pins, and stripper plates, do not form the plastic but are essential for the mold's mechanical operation. They ensure the mold opens and closes with micron-level alignment every single time.

Why Choose a Professional China Injection Mold Company?

Partnering with an experienced manufacturer ensures that these technical principles are applied correctly. From choosing the right tool steel (like P20 or S136) to optimizing the gate location, professional mold design minimizes long-term production costs and ensures high-yield manufacturing.

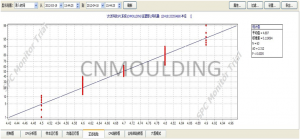

Injection Mold Process[/caption]

Injection Mold Process[/caption] Injection Mold Process[/caption]

Injection Mold Process[/caption]