With the rapid development of the automotive industry, especially the rapid development of new energy vehicles

(including hybrid, pure electric, and hydrogen energy) in recent years, the automotive industry has demand for lightweight, integrated, miniaturized, and electrified

auto parts Also increasing day by day.

Plastic is an indispensable material in the

automotive field and its process and performance requirements are increasingly

becoming everyone's attention. At the same time, higher requirements are also

placed on the R&D capabilities and rapid response capabilities of the material

suppliers.

Miniaturization of turbocharged engines

requires high-temperature resistance of plastic materials

The latest development trend of internal

combustion engines is miniaturization and intake supercharging (that is,

turbocharged high). The huge benefits brought by these two technologies are a

significant reduction in fuel consumption, an increase in engine power, and a

reduction in overall engine mass. For example, The two-piece structure design

of the previous engine intake manifold has been changed to an intake manifold

with an integrated intercooler.

This design puts forward higher

requirements for the high-temperature resistance and high strength of the

material. It needs to withstand high temperatures of 190°C and 230°C for a long

time and has excellent strength.

Electrification requires low precipitation

and neutrality of plastic materials

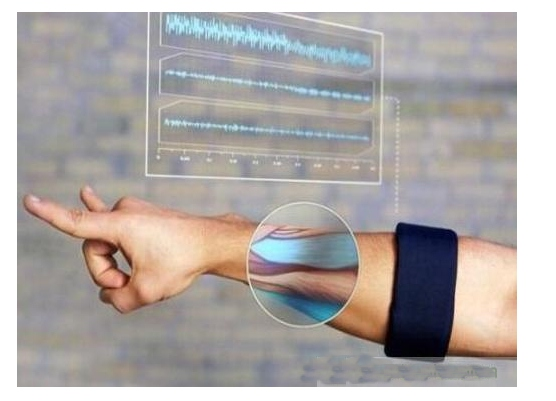

As more sensors have been placed in various

positions of the vehicle, the integration of electrification continues to

improve, and the requirements for materials of this electrified equipment are

more stringent than before, such as low precipitation (not to block the oil

circuit of the capillary structure), Electrically neutral (not to cause a short the circuit in the circuit), materials need to meet the requirements of relevant

laws and regulations (not to contain prohibited substances), etc.

Polyamide (nylon) materials are widely used

in the automotive industry for their excellent mechanical strength and

long-term heat resistance. Its heat resistance is related to the heat

stabilizer. Common heat-resistant stabilizers include metal salts (such as

copper iodide/copper halide, metal stearate, etc.) and aromatic amines (such as

aniline substances, etc.). With the increasing awareness of environmental

protection, some of these heat-resistant stabilizers have been banned by

relevant regulations due to their side effects. For example, the latest EU

regulations strictly control N, N'-diphenyl-p-phenylenediamine (DPPD) substances

.

New energy vehicle requirements for flame

retardant properties of plastic materials

With the rapid development of new energy

vehicles (including hybrid, pure electric, and hydrogen energy), related

standards for parts and materials in this field are also rapidly refined, for

example, requirements for different flame retardant systems, flame retardant

systems Cover roughly 5 types, namely: halogen flame retardant, nitrogen flame

retardant, inorganic flame retardant, phosphorus flame retardant and

nitrogen-phosphorus synergistic flame retardant; among them, the flame the retardant mechanism is divided into gas phase flame retardant and corrosive"

Carbonized" flame retardant, such as red phosphorus, inorganic flame

retardant, etc.

Different flame-retardant systems have

different flame-retardant effects, and at the same time have obvious changes in

the physical properties of the material (such as density, rigidity, and

toughness). So how to choose a flame-retardant system to match the

flame-retardant effect and mechanical strength requirements of the components

is a very complicated problem that must be solved.

New energy vehicle requirements for thermal

aging stability of materials

In the high-voltage parts of new energy

vehicles, according to regulatory requirements, bright orange materials are

required to mark the relevant parts as high-voltage areas. The components in

the high-voltage area tend to continue to heat up after the current is

connected. Therefore, most vehicle manufacturers also put forward related

thermal aging stability requirements for orange materials. For example, after

90℃+1000h thermal aging, the color change of RAL2003 shall not exceed

Darker orange such as RAL2008, RAL2009.

In the future automotive industry,

lightweight and weight reduction, electrification, high transmission

efficiency and miniaturization of turbocharged engines will surely become a

whole and become the indicators for the development and verification of most

highly integrated auto parts. . Material manufacturers also need to actively

respond to the market and improve material performance to meet the new

requirements of the automotive industry.