We are a good reputation company in plastic injection mold manufacturing and injection molding industries in Shanghai China, found in 1997.CNMOULDING offers a plastic injection molding service and specializes in various plastic moulds. automotive, home appliances, electronics, as well as general industrial OEM applications. Our company covers an area of more than 3500 square meters workshop, surrounded by convenient transportation. At present, our company reaches more than 100 employees and capital assets to more than 7 million RMB. Our capacity is 30-50 sets mould per month.

Our Company Mission

CNMOULDING mission is to be a professional, trustworthy, and creative toolmaker and injection molding supplier. We always keep the Layout at the top level, introduce a modernized management system, Go in for zero default. Make sure quality and techniques in the highest way. Therefore, We dedicate to make innovation and progress continue to be your better partner. enhance our technology and accumulate experience in mold building, injection molding, Rapid Prototyping

Thermoforming, Die casting, Painting and assembling, etc.

Our Company services include:

CAD design/mold flow analysis/DFM

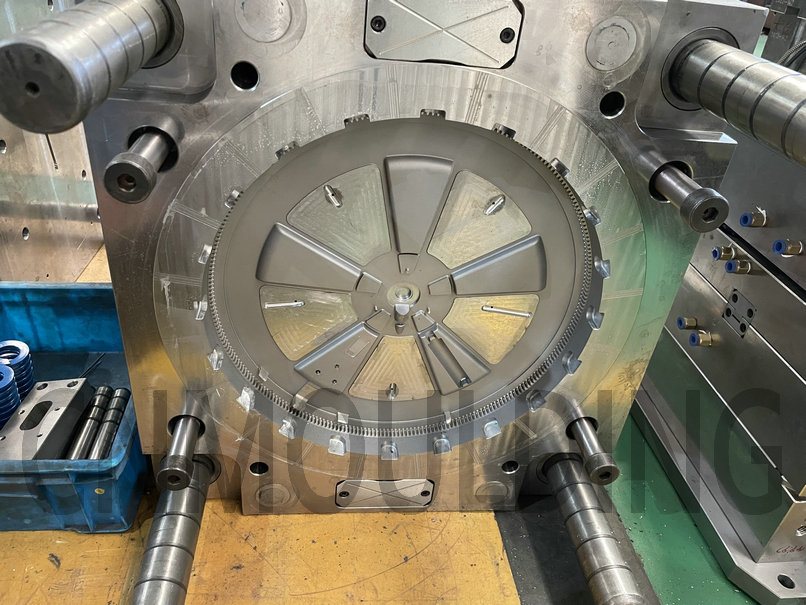

Custom injection mold making

Plastic injection molding

Rapid Prototyping

Thermoforming

Die casting

Painting and assembling

Why you select my company

1, Our employees have a richer work experience.

Our company employees engaged in mold manufacturing has 5 to 10 years of work experience,

For product design, mold manufacturing, and manufacturing process problems, we can easily handle

2, We provide direct factory prices and make cost transparent.

As you know there are more than 5000 trading companies in China, but Some of them concealed their property very well, It is hard to tell for a foreigner. normally they will take profit 30%.so we show the detailed cost in our website, Most traders can’t quote the price with this level. but these prices are normal prices for us and have proper profit.

3, We focus on providing a one-stop service for small and medium-sized companies.

We are a middle-size mold making and injection molding company, it is also one reason for a good price. We don’t need to pay for the huge administration fee compare to a big factory. We got ISO 9001-2015 certificate, it ensures our quality same as big factory. As everyone knows china’s mold is much cheaper than in the USA or Europe but injection molding will be more expensive because the resin price in China is 50% higher or double. But if you only produce 1,000-50,000 pcs. then China will have a big advantage. Moreover, we can make print, paint, and assembly in-house.it also saves a lot!

Injection molding is a manufacturing process for producing plastic injection molds from both thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mold cavity by a reciprocating screw or a ram injector, where the injection molded part cools and hardens to the configuration of the mold cavity. After a part is designed, usually by an industrial designer or an engineer, molds are then manufactured by an injection mold company, where it is assigned to a mold maker (or toolmaker). Injection molds are usually constructed using either steel or aluminum, and precision-machined to form the features of the desired parts. Injection molding is widely used for manufacturing a variety of parts, from the smallest component to the entire body panels of cars. Injection molding is the most common method of production, with some commonly made injection molded items including computer components to outdoor furniture.

Utilizes screw-type plunger to force molten plastic material into a mold cavity

Produces a solid or open-ended shape (typically a cavity and core shape) that conforms to the contour of the injection molded part.

Injection molds require the use of thermoplastic or thermoset materials

A parting line, sprue, and gate marks are present

Ejector pin marks are usually present on injection molds

Plastic injection molding is the preferred process for manufacturing plastic parts. Injection molds are used to create many things such as electronic housings, containers, bottle caps, automotive interiors, pocket combs, and most other plastic products available today. Plastic injection molds are ideal for producing high volumes of plastic parts, due to the ability to make multi-cavity injection molded parts, where multiple parts are made with one cycle. Some advantages of injection molding are high tolerances, repeatability, a wide range of material selection, low labor cost, minimal scrap losses, and little need to finish parts after molding. Some disadvantages of this process include an expensive tooling investment and the need to prototype, as some custom complex parts may encounter problems during the injection molding process such as warp or surface defects. Therefore, injection molded parts must be designed with careful molding consideration.

All in all, as a professional plastic design, prototype manufacturing, molding, system assembly service contract manufacturing company. We are actually an extension of the customer product development team. We can provide seamless transition throughout the new product introduction cycle and provide full ownership of the product from design to build. We operate 7 injection molding equipment and related secondary operations in Shanghai, China. Integrated system manufacturing units can meet all product development needs, from prototype to full production. One order, the assembly of a production site system has brought many benefits to the customer, and over the past 20 years has also invested a lot of money, including plastic and prototyping of concurrent engineering; improved mold / plastic design, interface, and bonding; Faster time to market; no inter-company marking; and lower shipping costs. Systems necessary to support such efforts, including supply management, test development, data tracking, inventory services, etc.