1. Optimize the Ejection Process

Adjust ejection parameters to minimize stress on delicate ejector pins.

Reduce ejection speed: Excessively high ejection speeds generate significant impact forces, increasing the risk of breakage in thin ejector pins. A moderate reduction in speed can mitigate this risk.

Implement multi-stage ejection: Utilize the multi-stage ejection capability of the injection molding machine. Initiate the first stage at a low speed and short stroke to release vacuum adhesion, followed by standard ejection in the second stage. This approach effectively reduces peak impact loads.

Verify ejection stroke: Ensure the stroke is precisely calibrated to fully eject the part without over-extension, which may cause the ejector pin to lose guidance support and become unstable.

Maintain proper lubrication: Regularly apply high-temperature mold release oil to the ejector pins to minimize friction between the pins and the mold core.

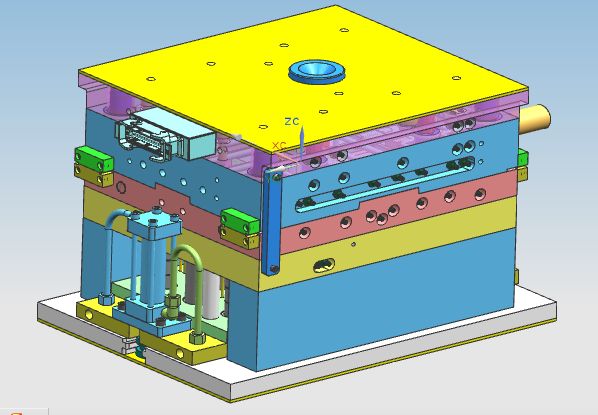

2. Revise Mold Design

The most effective and long-term solution is to replace fragile, undersized thimbles with larger-diameter counterparts.

This modification requires adjustments to the hole positions in both the mold core and the ejector plate. Although this involves higher initial costs, it provides a durable and reliable resolution.

3. Modify Ejection Methodology

When spatial constraints prevent increasing the pin diameter, alternative ejection mechanisms should be considered.

Use flat thimbles: In narrow regions such as rib areas, flat thimbles offer a greater cross-sectional area and superior resistance to bending compared to round thimbles.

For boss columns with high shrinkage forces, employ stripper pins, which provide a broader and more uniform ejection surface.

For deep cavities or thin-walled parts, consider air-assisted ejection systems. These introduce compressed air from within the cavity to disrupt vacuum formation, significantly reducing demolding resistance.

Apply push plate ejection: For large, deep-container components, push plates offer full-surface contact, distributing ejection force evenly and minimizing localized stress compared to point-contact ejector pins.

4. Enhance Mold Structural Integrity

Incorporate guide pillars: Install guide sleeves on the ejector plate to ensure precise alignment and smooth movement of the ejector system, thereby preventing lateral shear forces due to misalignment.

Polish ejector pin bores: Inspect and refinish worn pin holes to reduce friction and improve operational smoothness.

Inspect for and correct undercuts: Conduct a thorough mold inspection to identify any unintended undercuts that may contribute to excessive part retention force, and rectify them accordingly.