What will happen to the world economy in 2019? A large

number of uncertain factors have left the world economy in a fog, and overall,

anxiety and optimism coexist. Basically, the global economy will slow down in

2019. Since the beginning of 2018, emerging market economies have suffered from

capital outflows, weakening the economies of emerging countries, leading to

currency depreciation, rising inflation, and reduced household purchasing

power. In the second half of the year, some emerging markets broke out in a

currency crisis, geopolitical situations were once again tense, trade frictions

escalated, and the risk of a resurgence of the crisis was reshaping new growth

patterns through different forms.

In the global economic downturn in 2019, companies have

become increasingly difficult to survive. Especially for large and medium-sized

enterprises, faced with high labor costs, rental pressures, and rising raw

material prices. How to find the right supplier, reduce the procurement cost

and ensure the quality?

1, how to reduce procurement costs

Currently, companies are in a highly competitive and

rapidly changing environment, and competition has caused the industry's average

profit to fall. It is increasingly difficult for companies to establish or

maintain sustainable competitive advantage through sales and production; there

is still room for development in the procurement field that has been neglected

for many years.

Effectively reducing the overall cost of procurement and

integrating supplier capabilities through strategic procurement will become an

important source for leading companies to continuously reduce procurement costs

and enhance their competitive advantage. Therefore, the focus of procurement is

on how to choose suppliers, especially the supplier price comparison that pays

more attention to the transaction process. Through the competition of

suppliers, choose the lower price as the partner. Perhaps the blind pursuit of low

prices may lead to a decline in quality. If you cooperate with CN-MOULDING, you

don't have to worry about this problem. CN-MOULDING is a typical small and

medium-sized enterprise in China. The company is not too large. It is a real

manufacturing enterprise. CN-MOULDING can supply customers directly,

eliminating all the difference in the middle and reducing costs. The company coordinates Shanghai has geographical advantages, convenient import and export,

familiar with business operations, saving time and cost.

2, how to choose low-cost high-quality suppliers

Taking CN-MOULDING as an example, an injection mold

company was established in 1997 and has been a small and medium-sized private

enterprise for 20 years. Since its establishment, it has been focusing on mold

manufacturing and injection molding. Since 2001, it has been engaged in the foreign

trade business. It has a large customer base and recognition in Europe and

America. With its exquisite technology and rich experience, it has been

provided to customers in more than ten countries and regions. solution:

1. Help customers to properly adjust the wall thickness

of the product and find the best balance between product quality and production

cost.

2, predicting the appearance of weld defects, gas marks,

trapped gas, and other defects,

3, predict and control on the mold. Predict product

distortion,

4, Help customers to improve the product assembly

structure, the front design to avoid deformation.

5, rationally arrange the glue and cooling system to

achieve the best process and the most economical investment.

6, to provide optimized production process parameters to

help customers solve the problem of product injection production.

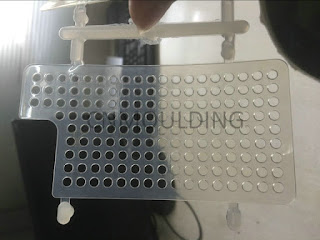

The following mold is produced by CN-MOULDING for

American customers. It is bulky, thin wall, complex in structure, high in

precision, and more difficult to de-mold the gas roof unit. At that time,

CN-MOULDING was not the first choice partner of customers, but more inclined to

have large companies on a large scale. In the eyes of customers, big companies

mean high quality, high standard, on-time delivery, after-sales service and so

on. But ignoring an important issue is the cost of procurement, the quality of

the mold is excellent, is the price equally satisfactory?

After the customer revealed that the original mold price

was 680,000 RMB, far exceeding their budget. Then the friends around me came to

Shanghai CN-MOULDING company to visit and inspect, and offered the quotation on

the spot, the total price was 476,000 RMB. They said that it is hard to

believe, after all, the price is only 70% of the previous company. It is also

doubtful that such a low price can really be achieved? Can you really guarantee

the quality of the mold? Is the after-sales service guaranteed? Wait for a series

of questions. CN-MOULDING has shown that the larger and more difficult mold

cases that have been done before have been shown to customers. Although

CN-MOULDING is a small and medium-sized enterprise, it has 20 years of

experience in mold manufacturing, and the cooperative companies have many

world-class companies. The business has also spread to more than ten countries

and regions. Numerous successful cooperation cases have enabled customers to

have confidence that CN-MOULDING is a professional, experienced and trustworthy

mold manufacturing company.

China's small businesses are fundamental to the vitality

of production

There are tens of thousands of small and medium-sized

enterprises in China. SMEs are the most dynamic and innovative enterprise

groups in China. At the same time, SMEs provide more than 50% of tax revenue,

create more than 60% of GDP, and complete more than 70% of invention patents,

providing 80%. More than % of urban jobs. SMEs have a pivotal position and have

unique advantages. With reasonable prices, rich experience and reliable quality,

they are gradually replacing the original large enterprises.

CN-MOULDING is a small and medium-sized enterprise in

China that is dynamic, innovative, and professional, and directly supplied to

foreign countries. In 2015, we obtained ISO9001:2000 quality certification!

With 20 years of integrity, 20 years of experience, and 20 years of quality

assurance and after-sales protection.